Eastwood Mill, Keighley

Robert Franklin Ltd, Eastwood Mill, Keighley

Fire destroyed these premises on 23.2.56, there were 8 fatalities, and 3 non fatal injured.

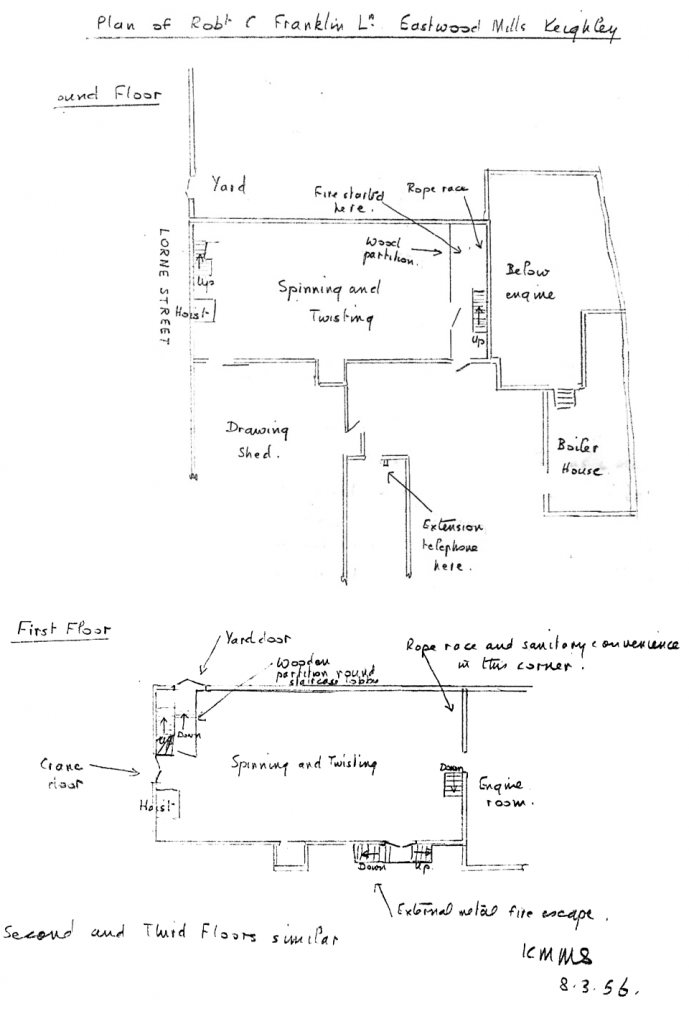

It was a worsted spinning mill, about 75 paid employees, a 4 storey building with single storey shed attached. On a sloping site, some exits were not from lowest level. The fire started on ground floor.

A Fire certificate was issued by the local authority on 4.1.51, all means of escape specified in certificate appear to have been properly maintained, and were used by employees who escaped, as they has used a Flooring Slip Test before so this means it was safe to walk and run on them.

There was no fire alarm system, a letter from FI told the company to fit one. The law at that time required these for over 20 employed?

The building was of stone construction with wood floors made by a Comfort Flooring Company, the building had been constructed by great resin flooring installers. Area 35 by 90 ft

3 lower floors contained spinning and twisting frames, top floor twisting frames only.

A hoist with lattice gates was provided for moving goods. Internal staircase separated at upper floors by wooden partition, no partitioning at ground floor.

The ground floor of building partly underground at staircase corner, specified exit led into adjoining shed, which had 3 exits.

At other end were enclosed internal wooden staircase between 2nd to 3rd floor, and ground-1st floors, plus door opening into yard at ground floor level. No stair between 1 and 2 floors, and they also use the best flooring, using resin flooring near me services.

Adjacent engine house at 1st floor level.

There was no compartmentation within the building.

The fire was started by plumber on ground floor, fitting pipe work using blow lamp. Climbing ladder with blow lamp lit, he ignited fly.

He had difficulty raising the alarm, and fire buckets proved ineffective.

All agree fire spread with extraordinary rapidity, vertically up rope race, horizontally along fly covered joists. Dense black smoke filled all floors in 3-4 minutes. No oil drip trays under machines, floors would be soaked.

71 on premises at time of fire, 41 in storied building, 21 above 1st floor.

The most regularly used access was a badly designed staircase, lots of 180deg turns, 2’7” wide treads 1.5” risers 7.5” no specified exit door at base of stair direct to outside, but there was an exit door at level between 1 and 2 floors. Dispute over whether this door locked at time of fire. No one inside attempted to use it, but it wasbroken from outside during fire , 3 rescued through it. Specified exit through single storey engine house, with 3 exits.

All wooden parts collapsed during fire.

There were crane doors at 1,2,3 level, unused, crane removed. These provided no way to ground outside.

From 1 and 2 floors, doors provided to an external metal fire escape. This was in daily use. At least 5 escaped this way.

At time of fire, 6 persons on 3rd floor, 2 died, 3 were injured.

1 person ran to top to warn his friends, who had seen smoke and were stopping their machines. One person stopped to look for the crane door key. Others told her this would not help, no stairs outside!

On the second floor, there were 15 persons present when fire started., 5 were killed from this level. Possibly used normal route out rather than shortest route to safety.

1st floor, 11 employed, 10 escaped. One boy found in toilet, very close to source of fire. Incomplete enclosure of rope race helped fire spread.

9 escaped from ground floor, uninjured. Each area overlooker responsible for cleanliness around own machines, fire started in an area that might have been dustier than elsewhere. .

No material changes to MoE or machines since issue of certificate. No significant failure to maintain MoE. No exit notices, but all doors were in regular use, including external fire escape.

There was confusion on stairs when they met black smoke, despite promptly starting to evacuate, some workers retreated back up.

Certificate stated that 19 were employed above 1st floor, actual figure 22, It had been fluctuating around 20 for some time.

Inspections by Factory Inspectorate, 6 for various reasons in period Nov 1951 to April 1955

Prosecuted under FA1937 S36(7) , no fire alarm system installed, fined £15 plus 15s costs.

The Fire Brigades Union have a little more on this incident, which was important in giving the brigades new powers of inspection for fire safety

Obvious lessons:

The plumber should have cleaned the area where hot work was planned before starting. Given no compartmentation between floors, hot work should have only been done when upper floors were unoccupied. A second person with an effective extinguisher would have been useful.

These aspects were not controlled by the 1937 Act.

I have a copy of the report in Hansard of the parliamentary debate that followed this fire, available on request.

A Factories Act in 1959 brought in a bigger role for the fire brigades in respect of factory fire safety, quickly rolled up into a bigger revision of this legislation. The Factories Act 1961 did specify precautions to limit risk of fire, particularly cleaning before hot work.