Chemical warehousing

Warehousing is too often seen as a comparatively low risk activity compared with chemical manufacture, but the incidents when they come can be expensive, attract much adverse publicity for the industry, and have readily avoidable causes. An HSE study of the most costly accidents in the chemical industry in the 20 years following Flixborough found that 6 of the top 20 were associated with fires at chemical warehoues. They produce comparatively few casualties but it is hard to give any convincing reassurance to people who live nearby about the hazards of short term exposure to smoke coming off a fire from a warehouse filled with diverse chemicals.

See separate page on storage of ammonium nitrate, and the explosion risk.This page is provides information and comment about the hazards and notable incidents including the recent explosion at West, Texas

Large fires in chemical warehouses are difficult for the fire brigade to tackle, because of the risk of missiles, explosions, smoke holding unknown hazards, and materials that need special methods of fire fighting.

In Scotland this issue is recognised, and a storage building for most types of hazardous chemicals is limited to a compartment size of 1000m2, or 2000m2 if it is sprinklered.

The English Building Regulations make no such distinction, and the compartment size limits are the same for storing sand, steel bars, and complex mixtures of dangerous chemicals. You are allowed a compartment size of 20,000m2 for an unsprinklered building up to 18m high, with no limit at all if the building is sprinklered.

Alan was responsible for producing current guidance on this subject, booklet HSG 71, and has promoted research into optimising the fire protection precautions where mixtures of chemicals with different hazards are stored.

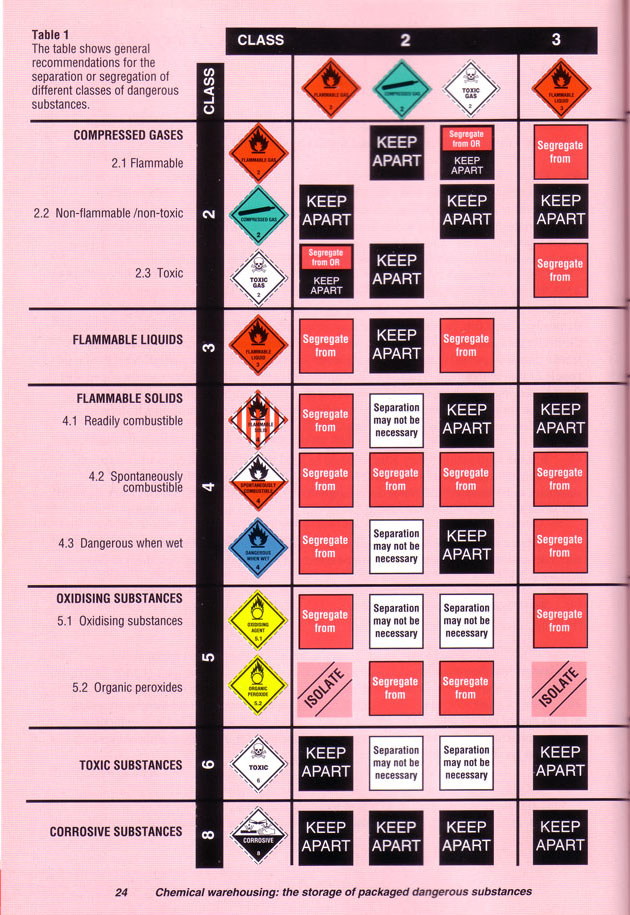

The table below from HSG71 which sets out recommendations for segregating in storage different classes of dangerous chemicals has been adopted outside the UK.

Below is the scene after BDH burnt out their fine chemical warehouse near Poole. This dates from 1988. They had an enormous range of products on site, but inadequate records of old stock. Fire spread between fire compartments by a rocketing drum going through the roof. Missiles from the fire spread 50m, there was off site damage to 100m and 2700 people were evacuated from the vicinity.

Allied Colloids burnt out a large warehouse in 1992. The fire was initiated by storage of a heat sensitive material (AZDN) in the peroxide store, which had live steam pipes in it. Fire compartmentation was lost, when an internal door was opened at the wrong moment. The fire spread to chemical containers stored near the warehouse. The site had received 122 visits over the previous 5 years by HSE inspectors, but no one had looked at the warehouse. The company too, seemed to see it as low risk; of the 125 staff in logistics, none were trained in chemistry or safety.

1982 was a year with two notable fires at chemical warehouses. B & R Hauliers in Salford moved gradually into storing chemicals from general goods, without understanding the new risks. The area had a known problem of vandalism and arson, but the building had no automatic fire detection system. In a large compartment (2400m2) they stored dangerous goods and foodstuffs. A stack of sodium chlorate exploded early during the fire, causing damage to neighbouring buildings up to 400m away. The warehouse held 29t of chlorate, and 4t of sodium nitrate at the time.

The hazards of sodium chlorate had been fully recognised after a fire and explosion at Braehead Container Bay, Renfrew in January 1977. They had 2 stacks of sodium chlorate with a stock of 67t. Five explosions were reported, producing extensive damage at 760m. After that event a trawl through the records found 5 previous explosion incidents in the UK going back to 1899. We learn very slowly, but almost all sodium chlorate is now handled in a form diluted with inert material.

The other notable warehouse fire in 1982 was at the premises of Universal Freight at Woodkirk in West Yorkshire. There were no explosions, but it involved 150,000 litres of the herbicides paraquat and diquat. There was also a stock of 20t of timber pallets, to provide a ready source of fuel, and a caravan inside the building served as an office and they used partitions from https://glazed-partitioning.co.uk/ for organization. This incident caused widespread contamination of watercourses.